Oil Pressure Puzzler Answers

The answers to the Oil Pressure Puzzler questions at Oil Pressure Puzzler are given below.

Preliminary Information

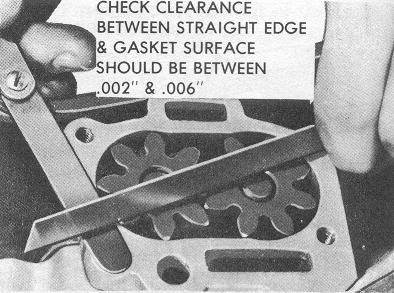

The photo below shows the oil pump body and gears:

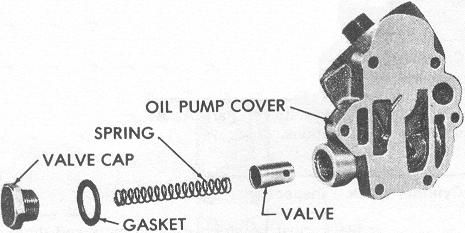

The photo below shows the oil pump cover and associated parts:

Notice in the first photo that the oil pump gears extend beyond the gasket surface of the oil pump body by 0.002" to 0.006". A gasket is required not only to seal the oil pump body to cover surfaces but is also required to give the proper clearance between the rotating oil pump gears and the oil pump body and the rotating oil pump gears and oil pump cover. This gasket must be greater than 0.006".

Since the answer to questions two and three are obvious after reviewing the preliminary information above, those questions will be answered first.

Puzzler Question #2 was:

Why did the engine distributor gear break each time the second oil pump cover was installed with no gasket?The Answer Is:

With no gasket installed, the oil pump cover jammed the gears up into the body when the oil pump cover bolts were tightened. Then, when the starter engaged, the jammed oil pump gears prevented the shaft to the distributor gear from rotating, thus causing the distributor gear to break which caused the snap/thump sound.Puzzler Question #3 was:

Why did the engine run properly after the second oil pump cover was installed with a gasket?The Answer Is:

With the gasket installed, the proper clearance was acquired between the rotating oil pump gears and the oil pump body and the rotating oil pump gears and oil pump cover.Puzzler Question #1 was:

Why did the engine run after installing the first oil pump cover with no gasket?The Answer Is (drum roll please...):

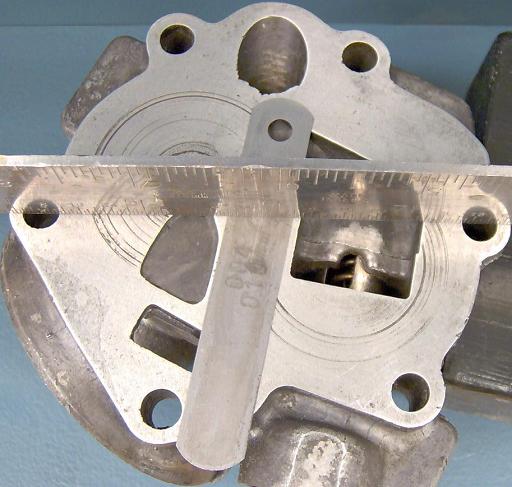

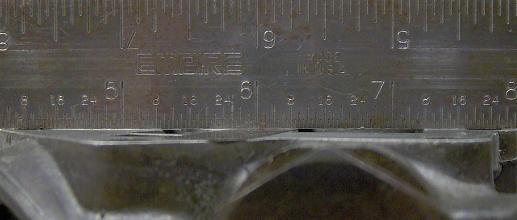

Because the oil pump cover was warped approximately 0.004", enough clearance existed between the rotating oil pump gears and the oil pump body and the rotating oil pump gears and oil pump cover to allow the distributor gear to rotate. The photos below show the warped oil pump cover:

The photo shows a 0.004" feeler gauge inserted between the straight edge and the center of the oil pump cover. Notice the circular scratches on the oil pump cover surface caused by the rotating oil pump gears. In the photo below, notice the light between the sides of the feeler gauge and the two ends of the oil pump cover that shows that the oil pump cover is indeed warped approximately 0.004".

The warped oil pump cover provided just enough clearance to permit the oil pump gears to rotate, thus not breaking the distributor gear etc..